Description

LEVELLER (2 LEVEL) FLOAT VALVES – DIAPHRAGM TYPE

Leveller 2 Level float valves allow for water level in the tank to drop to a set level before opening until the tank is refilled. Operating pressure 20kPa – 1200kPa, providing high flow (1275 lpm @ 1200kPa). Valve (1” BSPF Inlet x 11⁄4” BSPM Outlet – threaded outlet allows for connection to a diffuser tube) supplied complete with arm, cord & ball floats. Self-sealing adaptors with O-rings also supplied to adapt inlet to 11⁄4, 11⁄2” or 2” BSP. The Leveller Valve has a “SELF CLEANING PILOT” which allows its use in dirty or clean water.

Leveller Valve Features and Benefits

- HighperformancecosteffectiveReservoir/Tankvalve

- Adjustable Minimum and Maximum on off control(50mm-2.5 metre)

- Suitable for High/Lowpressures(0.2bar-12bar)

- Delivers high volumes of water quickly with unrestrictive full flow (1275 l/min at 12 bar)

- Patent pending “self cleaning pilot” for use in clean/dirty water conditions.

- Soft open and close action preventing valve bounce and water hammer

- Strong compact design

- Threaded outlet for use with a diffuser tube, ideal for high flows, eliminating turbulence

- Punch out anti-syphon holes for multi tank filling or diffuser installations

- Manufactured from strong, non corrosive U Vstabilised materials

• Valve supplied with Glass Fibre Reinforced Nylon valve body and 32, 40, 50mm Threaded Adaptors, Leveller Control,115mm Weighted HiViz Threaded Float, 140mm Blue Threaded Float, 2.5 Metre Cord.

The Leveller Valve is manufactured from Potable Water approved materials Leveller Valve Materials

• Diaphragm Valve Body – Glass Fibre Reinforced Nylon

• Diaphragm – Nitrile Rubber

• Guide Bush – Glass Fibre Reinforced Nylon

• Guide Retainer – Acetal

• Springs – Stainless Steel

• Split Pin – Stainless Steel

• Valve Body Cap – Acetal

• Guide Pin – Stainless Steel

• Valve Body Cap Nut – Glass Fibre Reinforced Nylon

• Pilot Seal – Nitrile Rubber

• Leveller Float Arm – Glass Fibre Reinforced Nylon

• Housing – Glass Fibre Reinforced Nylon

• Roller – Acetal

• Plunger Housing – Glass Fibre Reinforced Nylon

• Pivot Tube – Acetal

• Clamp Block – Glass Fibre Reinforced Nylon

• Clamp Bolt – Stainless Steel

• Cord Nut – Glass Fibre Reinforced Nylon

• Cord – Polyester

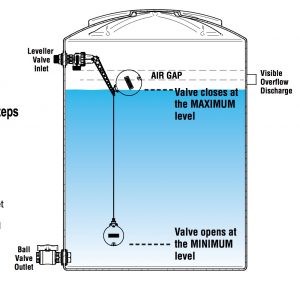

Leveller Valve Installation Steps

The maximum level is set by the position of the top float on the valve arm – allowing for maximum use of the tanks height.

The minimum water level is set by adjusting the length of the cord between the top float and bottom weighted float.

Leveller Valve Installation

- Install tank fitting into water tank / reservoir as per Hansen tank fitting installations steps Section Twelve Page 2

- Flush lines into water tank / reservoir before installing Leveller Valve into system.

- Thread O-Ring end of correct size adaptor into Leveller valve body.

- Thread Leveller Valve into Tank Fitting inside tank.

- Adjust position of float on Leveller Float Arm to set the upper water level allowing for air gap as required.

- Screw the Cord Nut into the Weighted Float.

-

Tie the cord to the bottom end of the Leveller Float Arm with the Weight at the required lower water level. Note: the lower water level must be above the tank outlet.

Fill the Weighted Float with water through the holes.

Frequently asked questions

Q I have noticed my pump switching on and off rapidly at times, will your Leveller Valve stop this?

A Yes, this is called cycling and can drastically reduce the life of your pump. The Hansen Leveller Valve is designed to control your pump safely by eliminating pump cycling and providing an adjustable water differential depth in your tank.

Q I only irrigate from my tank at night and have a timer on my bore pump. It will only fill my tank at night when I’m irrigating but I still find my bore pump is cycling when I’m irrigating. Will the Hansen Leveller Valve help in this situation?

A Yes, you will find the reservoir valve you are using at the moment is only supplying a flow close to your irrigation demand, with the Hansen Leveller Valve the flow delivery will be much higher and will allow your bore pump to run for less time as well as setting a differential in the tank to enable your pump to shut off for sensible periods.

Q In my dairy shed at peak water demand times I find my pump is cycling. As demand increases they run continuously and often cannot keep up, resulting in no water in troughs and other areas in my shed. Will your Leveller Valve fix this issue?

A Yes, as long as your pumps are sized correctly to cover your peak demand the Hansen Leveller Valve will help by delivering a much higher flow at a much lowerpressuree.g.400kPa(58psi)= 772 l/min (170 gpm)

Q For years now I have had problems with filling my tanks as my water supply can get very dirty at times. I believe I have purchased every valve on the market and all have let me down at some point, will the Hansen Leveller Valve finally fix my problem?

A Yes, our range of HiFlo Valves are designed to handle dirty water. With the Hansen Leveller Valve which is based

on our diaphragm valves it is unique in that it has a pin that cleans the pilot hole in the diaphragm every time it opens and closes. In addition to that the gap between the diaphragm and the valve body when open is a huge 14mm further reducing potential blockages.