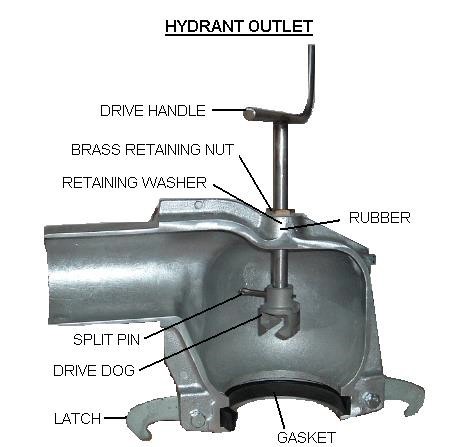

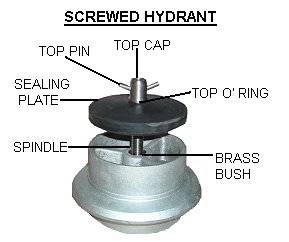

RJ Valve Riser Sealing Cap Spares

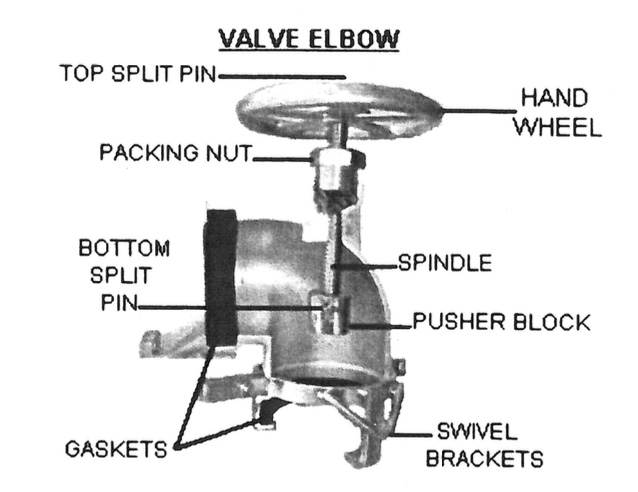

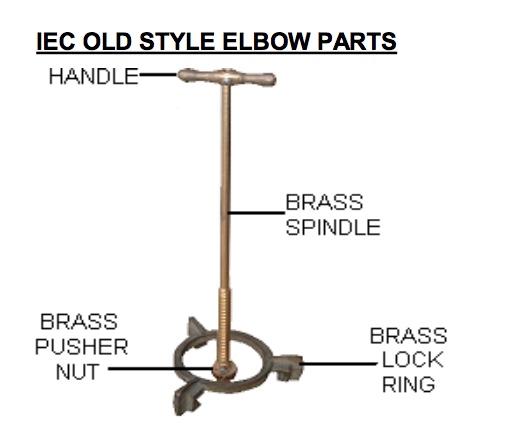

Spares for RJ Valve Elbow Extension

Spare Parts for RJ Valve Elbows

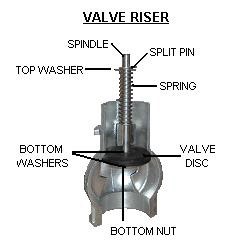

Spare Parts for RJ Valve Riser

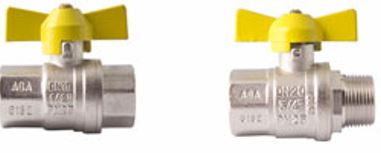

Gas Approved & Watermarked

Yellow Butterfly Handle

Standard equipment on E-Sport machines include

– Hot galvanizing frame & drum

– Solar energy drive with batteries and electric motor

– 4 speeds switch

– Automatic brake

– End rewinding stop

– Latch for engagement-disengagement

– 2 wheels sprinkler cart

– Sprinkler with nozzles’ series

– Automatic lifting of the sprinkler cart from working to shifting

position

– 2 m flexible hose with coupling

– Draw bar for tractor

– Hose guide system with no end screw

– CE mark and certification

32mm x 100m pe hose complete with Sime sprinkler (Funny) with nozzles 6, 7, 8

40mm x 110m pe hose complete with Sime sprinkler (Jolly) with nozzles 9, 10, 12

40mm x 140m pe hose complete with Sime sprinkler (Jolly) with nozzles 9, 10, 12

50mm x 150m pe hose complete with Sime sprinkler (Hydra) with nozzles 12, 14, 16

Specs and Data Charts

POA- Please contact us for a quote

MUSSEL Made from 1.6mm Duragal Steel with Cold Gal on Welds

*** WARNING — These Products will not fit or perform to their optimum level unless they are fitted with the foot valve specified

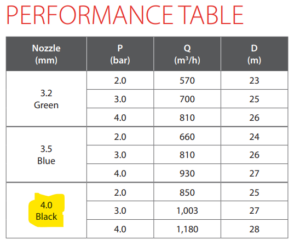

Carton of 6 – Bulk Buy clearance stock 4.0mm nozzles

423 AG – 4.0mm nozzles 1/2” Male, metal sprinkler, full & part circle with adjustable diffuser pin and plate,

anti-splash hammer

Product advantages:

▪ Specifically designed for use around field

edges and headlands, also an excellent,

heavy-duty, landscape irrigation sprinkler.

▪ Often used in bush fire suppression systems.

▪ Can be used as a part circle or full circle

sprinkler simply by flicking up the trip spring

▪ Special hammer ensures water stays within

boundaries

▪ Heavy-duty metal construction for enhanced

sprinkler life

MDR1/6B4- 170-500 kPa range, adjustable diff, 1/4” conn

MDR1/11S4 600-1000 kPa range, adjustable diff, 1/4” conn, on / off switch