POSEIDON PUMPS

named after the Greek God of water, symbolising strength in a turbulent environment. The modern Poseidon stands for engineering know-how and reliability in a modern age where the environment, precision manufacturing, reliability, efficiency and economics are the new norms that rule the waves. No longer are innefficient and wasteful pumps acceptable, ineffciencies cost time and valuable resources. Poseidon Pumps uses the most advanced hydro dynamic CFD computer software available in the market for pump impeller and casing design to optimise pump efficiencies and component reliabilty. Together with extensive R&D and pump testing in our state of the art computerised pump testing stations, has allowed us to create a highly efficient range of Poseidon pumps with low NPSH.

The Benefits

ENVIRONMENTALLY RESPONSIBLE

The Poseidon pump range are at the front line of environmentally friendly pumps. With the new patented (pending) SmartprimeTM automatic priming system, pump priming is clean without any discharges of pumped water or priming oil into the environment, as tends to happen with compressor / venturi based systems. Together with a highly efficient pump / engine package, the Poseidon product is environmentally friendly.

ADVANCED TECHNOLOGIES

Designed with the latest 3D pump CFD computer modeling software. Manufactured using the most advanced manufacturing technologies available.

RELIABILITY FOR PEACE OF MIND

Due to sound engineering practices employed,

the high quality accurately machined materials used and with the care taken in the nal assembly, these pumps are second to none for reliability and durability. With oversized pump sha s to reduce sha exing thereby eliminating premature sha failures. Oversized ball and tapered roller bearings for greater radial and axial loads, oil cooled and lubricated for a longer service life.

ADVANCED TECHNOLOGIES

Designed with the latest 3D pump CFD computer modeling so ware. Manufactured using the most advanced manufacturing technologies available.

HIGHLY EFFICIENT PUMPS

Designed and engineered with fully enclosed impellers for high pump e ciencies that only a quality produced product can deliver. Pump e ciencies of over 85% are achievable, coupled to quality European or North American high e cient engines, all meeting the latest worldwide EPA emission requirements.

MANUAL DRY PRIME SYSTEMS

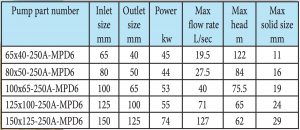

The Poseidon range of Dry Running Manual Prime pumps comes in 5 models which cover a ow range of up to 127L/sec and heads up to 122m.

The manual priming system is via a 6 cfm hand diaphragm pump mounted on the centrifugal pump.

Complete with an oil cooled mechanical seal system for dry running of the pump system, an essential feature of preventing premature mechanical seal failure. ese pumps are directly coupled to the engine without a bearing housing resulting in a very small foot print.

As this range of pumps can operate without any initial water charge in the casing, this takes all the worry out of the potential of destroying the mechanical seal when the pump runs out of water. Ideal for emergency services operations where the reliability of water supplies can vary greatly. Also the system does not need a foot valve but can be primed with the manual 6 cfm hand diaphragm priming pump up to 5 to 6m above the water source. e priming pump can be isolated from the main centrifugal pump via a small ball valve. Waste water with small so solids can also be pumped, this will require a strainer at the inlet of the suction hose to restrict oversized solids to enter the pump.

Specifications

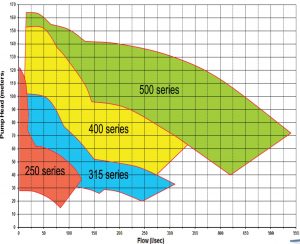

The Poseidon range of Dry Running Automatic Prime pumps comes in 18 models which cover a flow range of up to 540L/sec and heads up to 168m. Automatic priming via the patented SmartprimeTM 50 or 100 cfm diaphragm pump and priming tank. Complete with the oil cooled mechanical seal system for the dry running of the pump system.