Description

What are the operational benefits of the Marani Hard Hose Irrigator Range?

• Low pressure losses over the turbine

• Increased flow and low friction loss through HDPE pipe

• Fully Hot Dipped Galvanizing for longevity

• Top of the range computer controls for accurate water application

• Inclusion of a Solar Panel for trickle feeding batteries (optional extra)

Is workplace safety a concern to your customer? Are they looking for a machine that is easy to operate as well as safe?

With the inclusion of panels and guards on the Marani Hard Hose Irrigators, the risk of injury is considerably reduced.

Performance charts are available for the Marani Hard Hose Range. Just call or email our office with the model\s you are after and one of our Sales Team members will be more than happy to send them through to you. When requesting the charts, please also let the Sales Team know which sprinkler\gun you are interested in as this will change the performance data for the machine.

Marani has one of the largest specific ranges of poly reel irrigators available in all markets worldwide ranging from a 40mm to a 160mm machine.

Every machine is complete with manuals, instruction stickers, spare parts lists and performance sheets to make the end user run the machine very easily by themselves.

Features: There are many features that allow our Marani Hard Hose Irrigators to stand out from the competitors, here are just a few:

- Fully Galvanized

- Corrosion resistance

- Extra durability

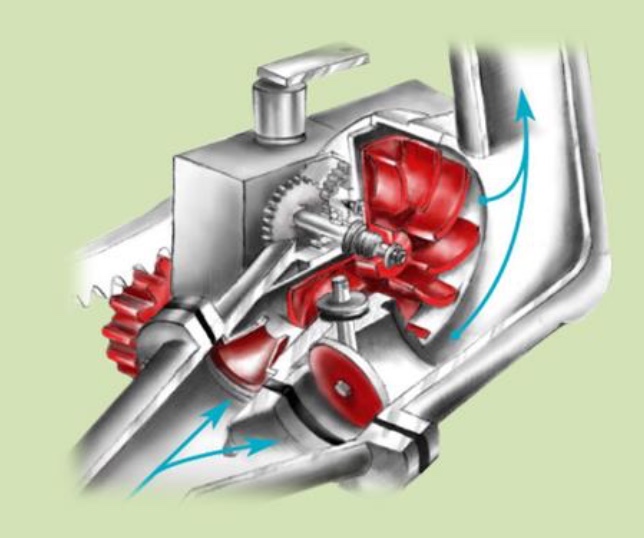

Fourth Generation Choke Flow

- Lower pressure loss over turbine

- More economical to run

- Gives a wider speed control range Direct coupled to gearbox

PE Hose

- Manufactured to resist heavy drags

- Will work at high pressures

Tachometer

- Retraction speed can be instantly read out

Drum Supports

- Drums are supported by large water proof bearings giving an increase in drum life

Hose Guide System – Scroll Bar

- Guarantees a perfect layering of the PE hose Reduces hose wear to a minimum

Gearbox

- Single, 3, 4 & 6 Speed gearboxes

- Ease of speed changing

Turbine system for GT Models

Marani Fourth Generation Turbine and Gearbox used on GT Machines are proven for Low Pressure applications and the Gearbox has been used for Both Gun Trolley Boom Irrigators for over 10 years.

The Choked-Flow Turbine with built in bypass is flanged directly to the Gearbox. This also eliminates a Transmission belt and external by pass. This makes the system reliable from a performance point of view Turbine is made with special Aluminium and machined using CNC marching Centre.

Turbine system for GTS and ITS models

No back-stop is needed. When the Gear Leaver is in the middle position the Drum is locked for Transport

With the Gear shift in correct position the reel will not turn. This makes it Impossible to break gearbox by winding up hose with PTO drive.

You can also easily see what speed you are in with the top gear change: 1-2-3-4.

- With the Lower change when in the Left position: hose is ready to pull-out & PTO wind-up.

- Centre position: drum lock down for transport

- Right position: working position

- If a Foreign Object jams up the impeller just reverse the impeller by turning the outlet shaft next to turbine.

Standard Equipment

-

Hydraulic lifting device of trolley Hydraulic rotation of turntable

Hydraulic feet

Hydraulic lift of drawbarHydraulic system by rapid couplings to tractor

4 Speed gearbox

PTO

Hot galvanized chassis and reel Safety guards

Tachometer

Turbine mounted on the gearbox with built-in bypassGalvanized 5 wheel raingun trolley mounted on variable hard rubber wheels

Winding handle

Pressure gauge (glycerine bath) Water Inlet Shut-Off Valve

Speed equalizer

Flexible connection pipe with storage reel

Four wheel chassis on 125Ø and 140Ø machines as standard