Description

Application

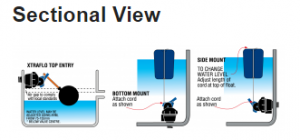

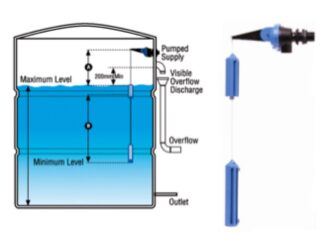

Large Troughs, High Demand Compact armless diaphragm valve with full-flow high volume fill. The valve has a 25mm water level differential between opening and closing, reducing pump motor overload. Full-flow operation, the pump runs unrestricted until trough is full. Large Troughs and Header Tanks Requiring Backflow Prevention Use the adjustable arm top-entry XtraFlo valve for above water fill applications and backflow prevention. Arm length is adjustable to set water level and for greater opening and closing differential reducing pump wear

Features and Benefits

- Long life

- High flow

- Armless – Less damage from stock (excluding top entry version)

- Full on, full off

- Bottom, side or top mount

- Long tail and top entry version available

- UV stabilised and corrosion resistant

- All materials AS4020 approved (Water Quality Standard)

-

Specifications

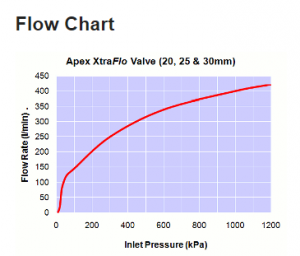

- Working pressure: 30 – 1200 kPa (4 – 175 psi)

- Maximum water temperature: 60°C

- Minimum Water Temperature: 1°C

In areas where the temperature can be lower than 1°C (minimum service temperature) trough valves must be installed as bottom or side entry but NOT top entry.

- PATENTS

- New Zealand patent No. 328862

- Australian patent No. 736446

- RSA patent No. 736446

Installation

- Flush lines thoroughly

- Use thread seal tape and hand tighten

- Set float and tie off cord

- To lock the valve in the closed position, jam the cord at the cleat lock with valve closed.

Cleaning

- Unscrew the cap using the Trough Mate tool

- Check that the lever operates freely*

- Remove the diaphragm, clean, inspect for wear or damage*, clean filter

- Clean and inspect the seat

- Lightly lubricate the jet centre slide & diaphragm seal with silicone grease

- Place the diaphragm in the body

- Screw the cap back on to the valve body

- Tighten with the Trough Mate tool, aligning the cord cleat of the cap opposite the body outlet

*If the valve requires new parts, obtain and fit a repair kit (RKXF).