Description

Automatic Self-Cleaning Water Filters 50 – 100mm (2”- 4”)

Electric Control

Supplied with electric controls using the 240 VAC Talgil control panel allowing backwash both by pres- sure differential and time.

All prices are for filters with 100 – 800 micron fine screens. For 50 & 80 micron screens please contact us for extra cost.

FILTAWORX® range of fully automatic self cleaning filters have been designed and built in Australia by an experienced team of engineers using the latest 3D CAD software. FILTAWORX® filters are one of the most technically

innovative self-cleaning filters available, combining proven high performance, reliability and economy in a compact robust design. Features include:

- ▲ Stainless steel filter body as standard.

- ▲ All parts are made of corrosion resistant materials.

- ▲ Fully automatic back flush operation.

- ▲ Available with hydraulic or electric controls.

- ▲ Large filtration area.

- ▲ Wide range of fine screen sizes, 50 to 800 microns.

- ▲ Standard sizes from DN50 to DN350 (2” – 14”).

- ▲ Pressure rating of PN10 as standard. (Max. operating pressure 1000 kPa (PN10))

- ▲ Simple and quick installation.

- ▲ Full support and after sales service.

- ▲ Designed, built and tested in Australia.

Advantages of Filterworks automatic Filters

Stainless Steel body for corrosion resistance in most environments.

Cleaning Mechanism:

The key feature to FILTAWORX® performance and reliability is the use of the escaping backflush water to rotate the internal cleaning mechanism inside the filter vessel. No external motor, mechanism or power is required, reducing the number of moving/wearing parts to a minimum.

Automatic Operation of the self cleaning backflush cycle is achieved when a pre-set pressure drop (40 – 50 kPa) across the filter is reached. 100% cleaning as every spot on the fine screen surface is cleaned with a high velocity, aggressive backflush flow.

No External Power is required (when using the hydraulic controlled filter). All functions are powered by the line pressure only. All controls required come complete with the filter.

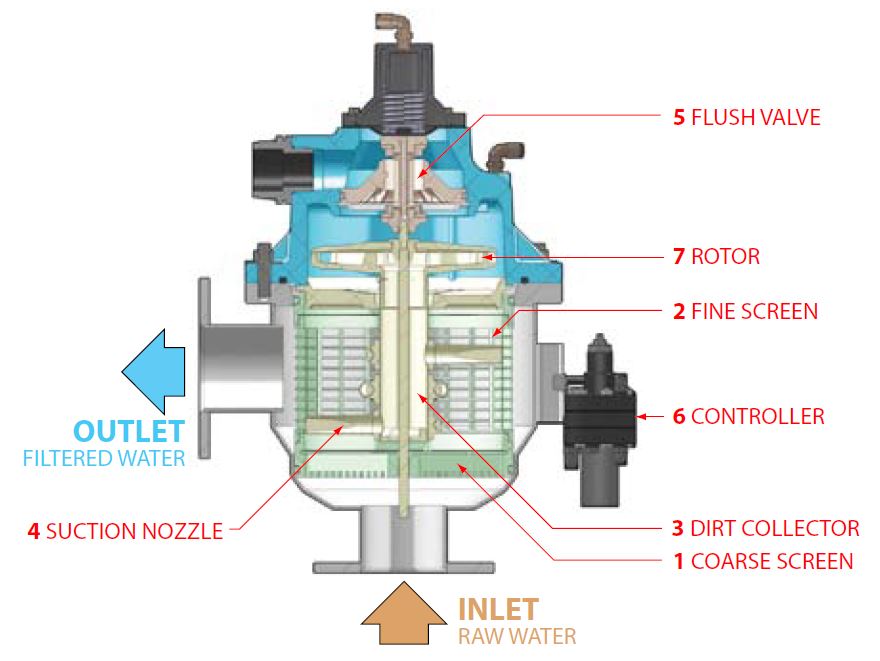

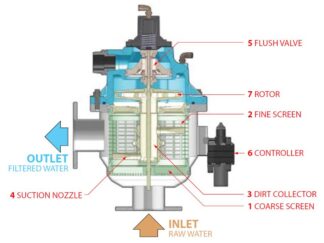

How FILTAWORX® Works

Uninterrupted Flow during the backflush cycle. More Screen Area than any other comparable filter available.

Positive Filtration using a precision 316 stainless steel mesh screen.

Wide Range of Filtration screen sizes available from 50 to 800 micron enabling correct selection for each application. Screens can easily be replaced on-site to alter the degree of filtration if required.

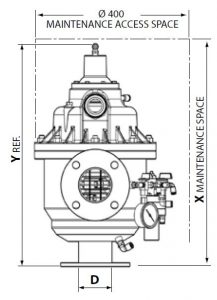

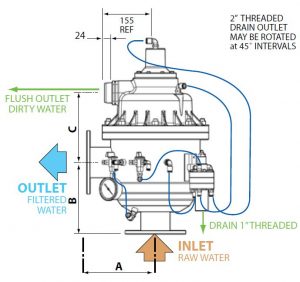

Compact and Simple Installation can be mounted in any position or orientation, with minimal space requirements.

High Reliability due to minimal moving parts, simple design and robust construction make FILTAWORX filters virtually maintenance free.

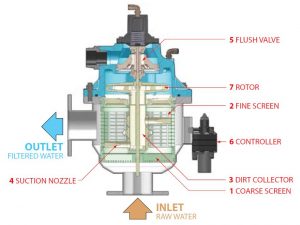

During normal filtering mode the raw water enters the Inlet of the filter, passes through the Coarse Screen (1), (this removes large debris that may obstruct the lower mechanism). Water then travels to the inside and through the Fine Screen (2) to the Outlet.

The solids in the water are trapped on the Fine Screen (2), eventually causing a pressure drop (DP) across the filter. At a pressure drop of 40 – 50 kPa the Controller (6) activates the cleaning cycle by opening the Flush Valve (5) to drain (atmosphere).

The interconnection of the Suction Nozzles (4) via the Dirt Collector (3) to the Drain causes a back flushing or ‘vacuum clean’ effect on the Fine Screen (2) with a high

velocity suction jet of water from the clean outlet side of the screen, removing the dirt on the screen as it passes through.

The water escaping via the Rotor (7) causes the Dirt Collector and Suction Nozzle assembly (3 & 4) to rotate. The Flushing Valve (5) allows this assembly down the length of the Fine Screen (2) in a spiralling motion, cleaning the entire screen surface area in approximately 5 seconds. The Flushing Valve (5) closes, and returns the mechanism back to its original position, ready for the next cycle. Cleaning also occurs on the return stroke.

Typical Application Areas

Irrigation

For the protection of all types of irrigation systems including: drip, micro jet, sprinkler and golf course irrigation systems, from all types of sources including treated effluent.

Cooling Towers and Process Water

Removal of algae, sludge, pipe scale, process impurities and atmospheric contamination, thereby maximising heat transfer efficiency, reducing maintenance, energy and chemical treatment costs of up to 30-50%. Significant reductions in sludge build-up in basins that sustains and shields legionella bacteria, ensuring a healthier & safer environment.

Equipment Protection

For pump gland seals, bearings, compressors, valves, etc.

Nozzle Protection

Eliminates blocked nozzles, keeping them clean and open thereby reducing maintenance.

Membrane & UV Protection

Removing problem sized solids that reduce the effectiveness of membranes and UV.

Effluent and Water Re-Use

Allows the re-use/recycling of effluent and other poor quality water within water treatment plants, industrial process systems, pulp and paper mills, mines, irrigation etc.

Town Water Supply

Removes algae, organisms, sand and silt from surface water streams, dams, reservoirs and bores, reducing chemical treatment and maintenance costs.

Surface and Ground Water

For protection of plant and equipment from contamination found in sea, rivers, dams, bores, and other water sources.

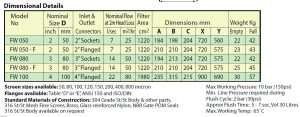

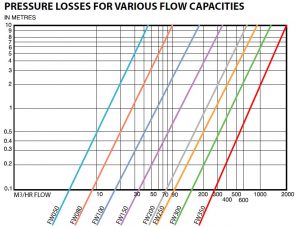

Technical Specifications

Selecting the right filter

Selecting the right FILTAWORX® filter for your particular application is crucial in achieving the best result. We recommend it be done in consultation with your FILTAWORX® dealer or Triangle Waterquip, who have extensive experience and know-how to assist you.

The following information will help you and us make the correct selection.

- The application and equipment you are protecting.

- Maximum and minimum flow rate that the filter will need to handle.

- System operating pressure, and pump details/curve if available.

- Level of filtration/screen size required.

- Dirt loading (Total Suspended Solids – TSS) of the water, if known.

- Type of solids that are present, i.e. sand, algae, paper fibre, etc.

- Filter control logic other than standard that may

be required. - Water temperature and any chemical/corrosiveness content if known.